Disc Fliter

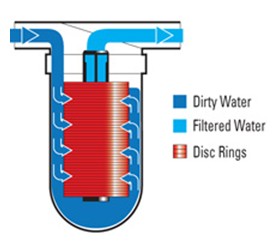

Disc Filtration Systems operate using a specially designed disc filtration technology.

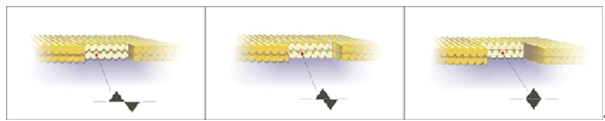

Thin, color-coded polypropylene discs are diagonally grooved on both sides to a specific micron size. A series of these discs are then stacked and compressed on a specially designed spine. When stacked, the groove on top runs opposite to the groove below, creating a filtration element with a statistically significant series of valleys and traps for solids. The stack is enclosed in an anticorrosion and pressure resistant housing.

During the filtration process, the filtration discs are tightly compressed together by the spring's power and the differential pressure, thus providing high filtration efficiency. Filtration occurs while water is percolating from the peripheral end to the core of the element. Depending on the micron rating, there are from 18 (in 400 micron discs) to32 (in 20 micron discs) stopping points in each track, thus creating the unique in-depth filtration

.Size: 3" & 4" Disc filter Batteries

1" - 10" inlet/outlet manifold diameter

.Capacity: Medium and High flow (50-500 m3/hr and higher)

.Operation: Modular, Semi Automatic Disc Filtration System

Features:

.Micron-precise filtration of solids.

.Innovative filter design captures and retains large amounts of solids.

.Long-term operation with little maintenance.

.Operation is easy and requires no special tools.

.Continuous flow during wash.